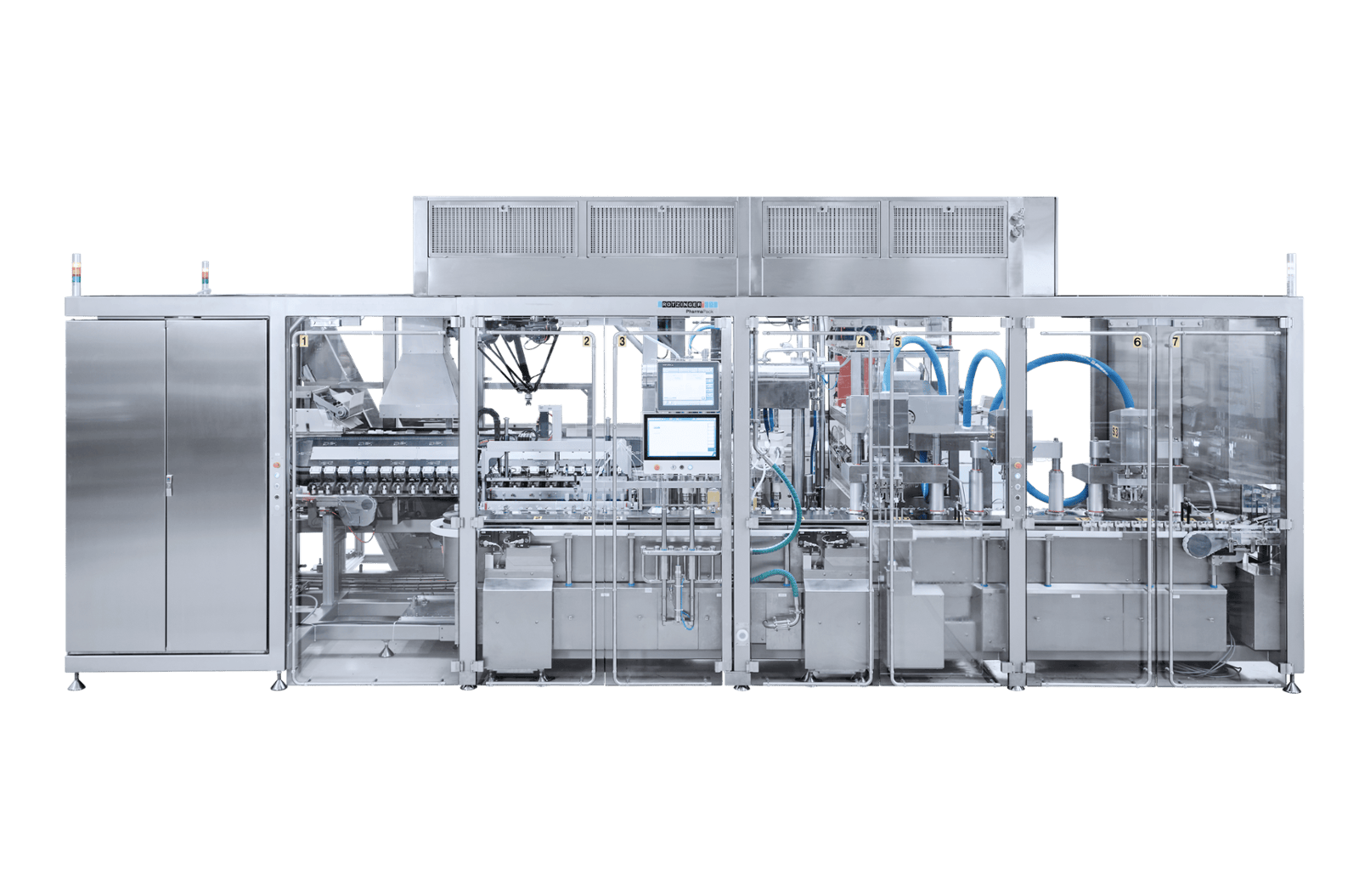

Introducing VarioFill

Setting new standards in filling and capping technology

Introducing VarioFill

The latest advancement in filling and capping technology

VarioFill - The most flexible and compact solution of its kind

Let's enter a new level of opportunities together.

Product variety continues to expand, and personalized products are gaining increasing importance in all kinds of industries.

With the development of VarioFill, we have redefined primary packaging flexibility and efficiency. Equipped with state-of-the-art technology, the platform is universally applicable to fill a wide variety of products – whether they are liquid, viscous, in tablet, capsule or powder form.

About VarioFill

Robotic, mechanical or manual bottle infeed

Depending on the product and production requirements, we integrate and combine the appropriate feeding modules. The options range from turntables, robotic or mechanical bottle unscrambler to manual feeding systems.

Air rinsing of the bottle

The VarioFill fully integrates an air rinsing module that uses filtered air and vacuum sucking to ensure thorough, hygienic cleaning inside each bottle.

Precise filling of products from low to high viscosity

Designed for versatility, the filling station is available with different dosing technologies — piston pump, peristaltic pump, or time‑pressure — covering fill volumes from 1 to 160 ml. Tool‑less, quick‑change nozzles handle a wide range of products and viscosities. To protect product integrity, bottles are nitrogen‑purged before filling, reducing oxygen exposure and helping prevent oxidation and spoilage.

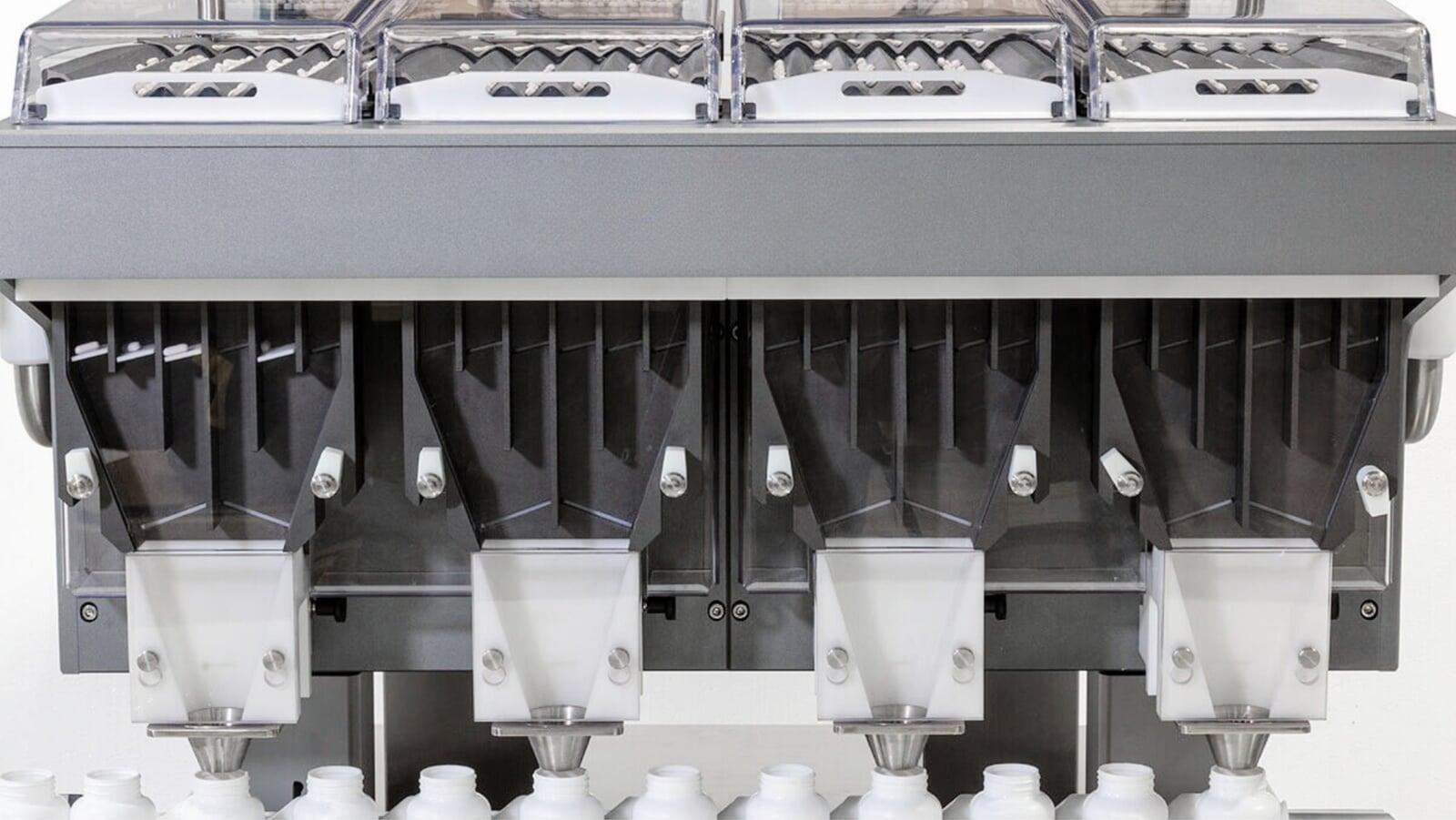

Filling any kind of oral solid dosage

For solid applications, like tablets, dragees or capsules, the VarioFill integrates one or multiple counting modules. Benefit from fast, tool‑less format changeovers and the option to integrate several cappers maintaining a compact footprint to boost your line flexibility.

The right closure type

At one or more flexibly configurable closure stations, containers can be fitted with any type of closure, including snap-on, screw, pump, and crimp.

Future expansions are easy to implement by adding or reconfiguring capping modules.

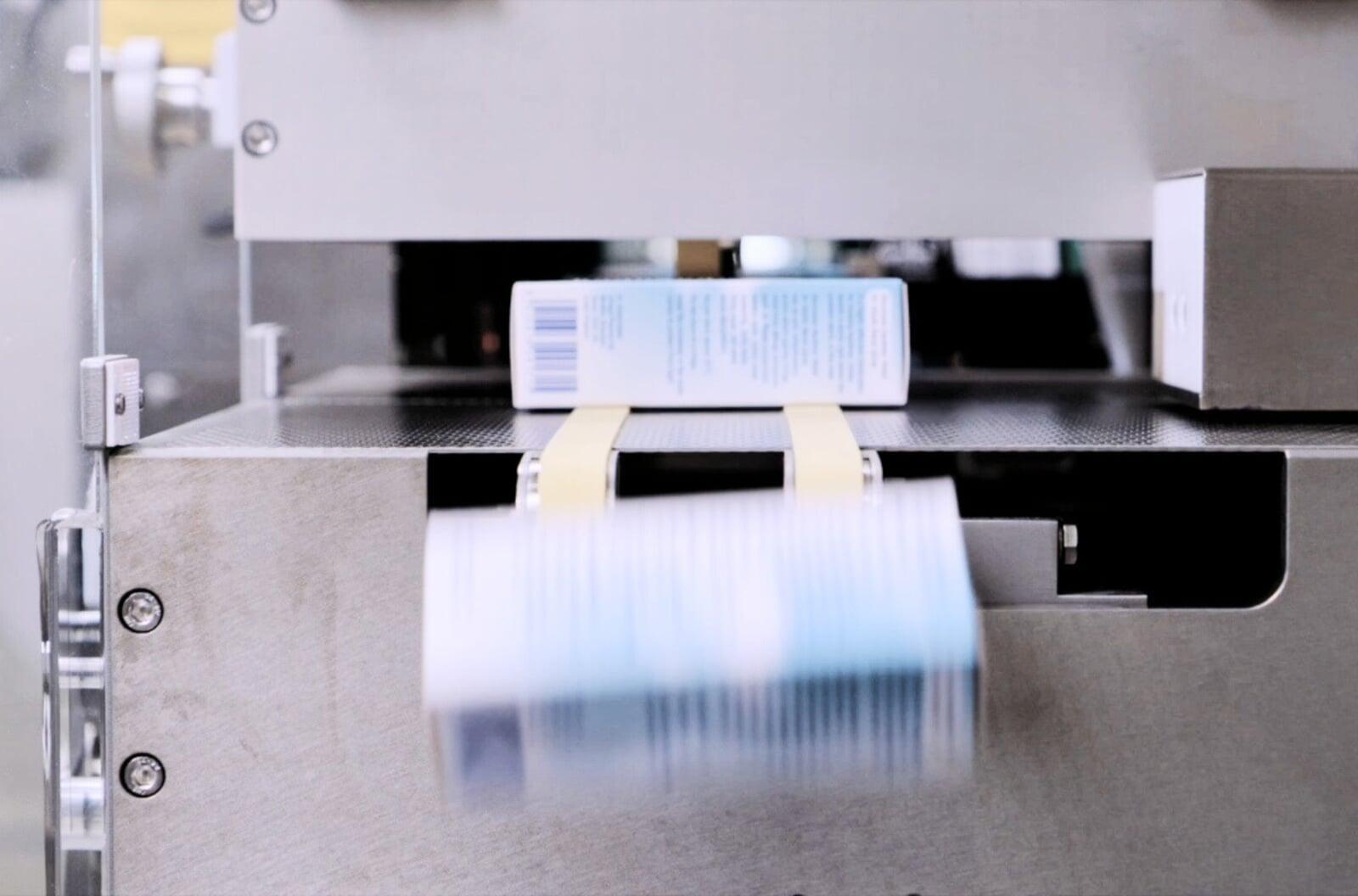

The appropriate downstream equipment

Our portfolio ranges from individual machines to turnkey packaging systems, including filling and capping machines as well as labelling, cartoning and serialization/aggregation solutions for product traceability. In addition,we offer solutions for the digitalization of production and packaging processes. Tell us about your project and we will figure out the best solution for you.

Elevate your production at every step

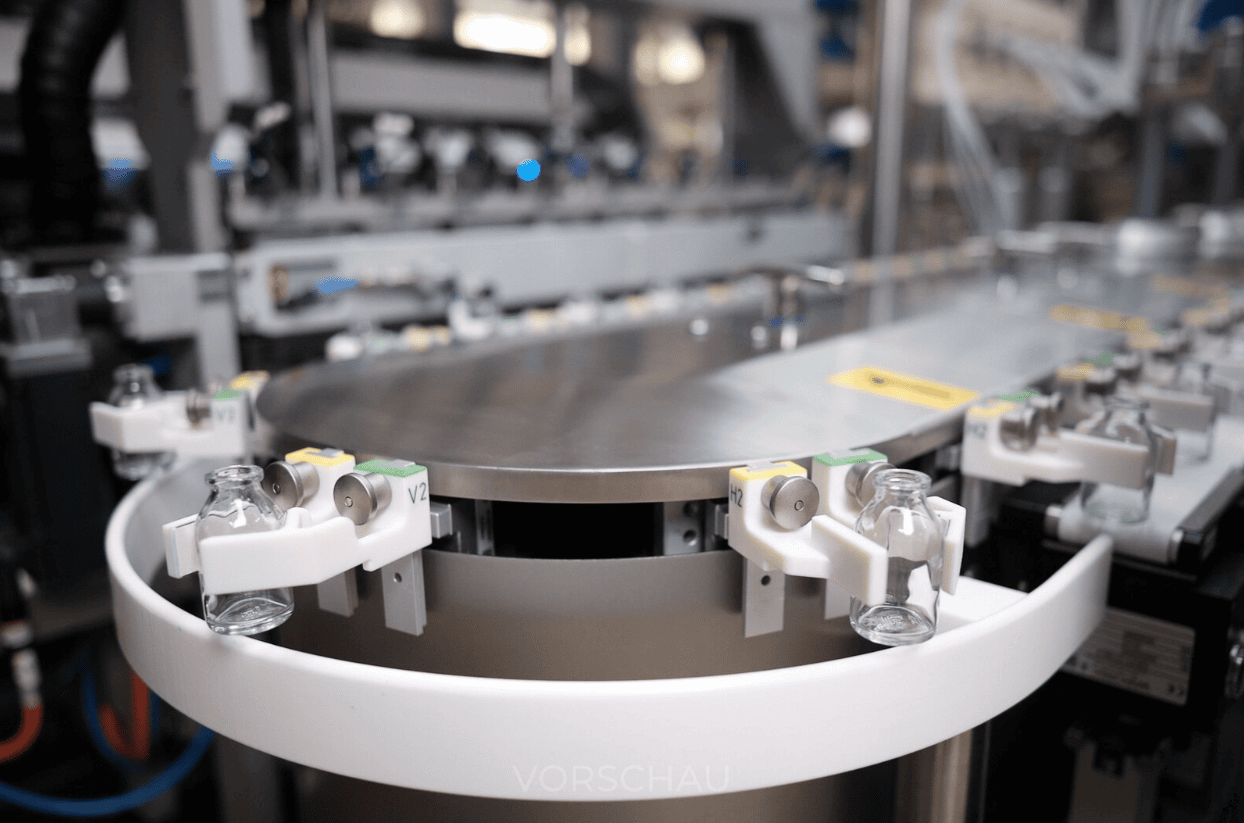

Intelligent transport system

Thanks to our intelligent transport system, bottle handling is both gentle and efficient. Unlike traditional systems, we need no pucks to ensure bottles are transported safely – even with unconventional geometries. This guarantees that your products remain perfect in appearance and ready for the market, which is particularly beneficial in aesthetically sensitive industries.

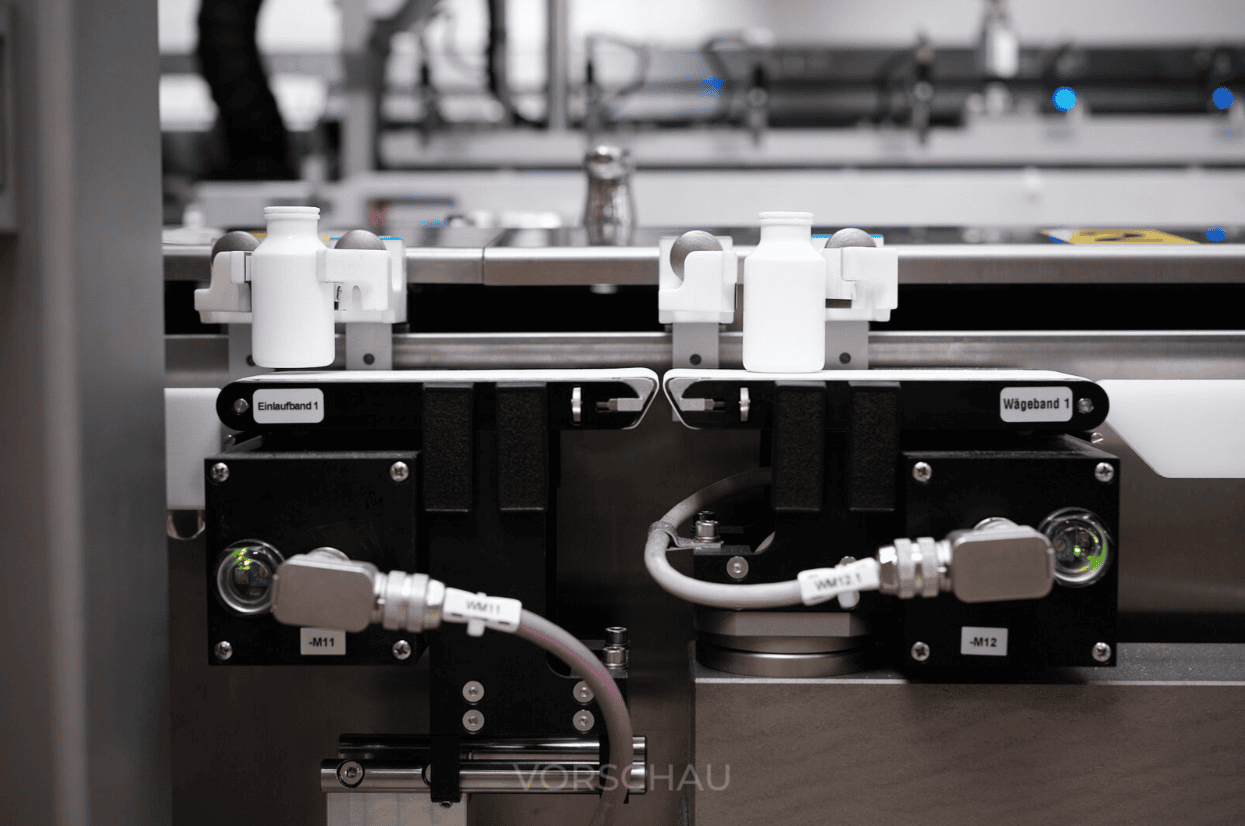

100 % In-Process-Control

Each container is individually weighed both before and after the filling process. This ensures that the exact amount of product is delivered every time.

Tool-less format changeover

VarioFill is specifically engineered to excel in environments characterized by frequent product changes.

Repeatable and validated cleaning results

Thanks to the integrated CIP (Clean-in-Place) system, VarioFill fully automates cleaning of product‑contact parts in the filling area by moving them into the cleaning position, cleaning them thoroughly, and returning them to the production position.

Your key takeaways

50 % less space required

VarioFill is the most compact solution of its kind. It combines bottle unscrambling, air rinsing, filling and capping, all on one compact platform.

It enables more than 50 percent space saving compared to conventional or comparable solutions on the market.

Flexibility in all aspects

Liquid, viscous, powdery, solid (tablets,

capsules)

materials and shapes

types, e. g. plugs, screw caps, press-on

caps, ROPP caps, measuring cups and

pumps

360ml

Guaranteed future adaptability

Contact us

Need further information?

Are you interested in VarioFill and require more information? Please let us know. We would be happy to support you and discuss your filling and capping project.

About Rotzinger Group

The Rotzinger Group, headquartered in Kaiseraugst, Switzerland, is a leading provider of customized processing and packaging solutions. The group comprises seven specialized members: Demaurex, Hansella, MF-hamburg, Packfeeder, Rotzinger, Rotzinger PharmaPack, and Transver.

The group offers individual equipment and turnkey systems for the production and processing of confectionery as well as for the packaging of food, pharmaceuticals, cosmetics and a wide range of other products. Additionally, the Rotzinger Group provides solutions for the digitalization and networking of production and packaging processes. Rotzinger offers customers a comprehensive 360-degree lifecycle service.

© 2025 ROTZINGER Group Imprint Privacy policy Legal notice Terms & conditions Cookie settings